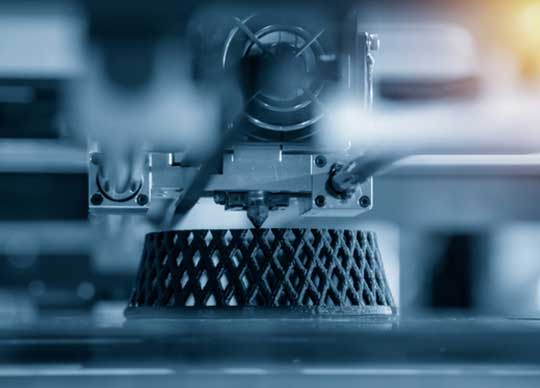

Combining additive manufacturing, or 3D printing with new sustainable materials, allows for a more flexible and resource-efficient production.

But for companies to be able to fully utilize the strength of the technology, support is needed in every step along the supply chain ranging from development of new business models to product design and testing in a real production environment. Therefore, RISE is opening up the Application Center for Additive Manufacturing together with industrial and academic partners.

Additive manufacturing enables a paradigm shift for the industry and is relevant for many sectors such as the aerospace, space, automotive, telecom, maritime, and consumer goods to name a few. Some of the advantages are the mass customization enabling unique tailor-made components that are produced with minimal material waste and that are optimized with regards to their weight. The global market for additive manufacturing is expected to continue to grow, and for metallic materials the market is expected to increase by a factor of two by 2025.

It is important that Sweden continues to invest in additive manufacturing to strengthen its position in this rapidly growing market.

“By gathering end users, suppliers of services, technology and materials with our researchers and experts at RISE, the Application Center for Additive Manufacturing enable us to form a robust national ecosystem for additive manufacturing in Sweden” says Seyed Hosseini, Director of Application Center for Additive Manufacturing.

“The center is a good example of how we gather expertise along the entire value chain and create a way to accelerate digital development in the Swedish industry. Additive manufacturing has great potential and now RISE can boost this transformation in taking important steps forward” says Pia Sandvik, CEO at RISE.

“Additive manufacturing is one of the new resource-efficient manufacturing technologies that, in addition to more circular material flows, is needed to make the future industry more sustainable. The investment in the Application Center for Additive Manufacturing both broadens and strengthens Västra Götaland’s position in innovation and sustainable and digital manufacturing technologies” says Kristina Jonäng (C), chair of the regional development committee in the Västra Götaland region.

The target group for the center is manufacturing companies, both large and small and medium-sized, but also suppliers of materials, software and equipment for additive manufacturing. The partnership provides the opportunity to take full advantage of the skills and infrastructure that exist and as a partner you also contribute to the center. With the help of the center, the threshold to test and evaluate the technology can be reduced.

“To be successful in additive manufacturing, you have to take care of the entire process, from equipment, printing process, finishing processes to quality assurance of the components. These are issues that need to be addressed, and we cannot do it ourselves, but cooperation between several parties is required” says Vladimir Navrotsky, Vice President Technology and Innovation, Siemens Energy.

“I hope that the results of the evaluations we do within the center will lead us to be mature in making our own decisions about which processes we will roll out in different operations and that we get a good decision basis for our own strategy going forward” says Johan Svenningstorp, Director Research and Technology Development Truck Operations, Volvo Group.

“It is vital for Swedish industry to increase research in the field of additive manufacturing because large parts of the global transport industry invest heavily in the field. We need an expansion of Swedish high-tech industry to get competition on equal terms globally. For Ericsson’s products, additive manufacturing can lead to a reduction of energy needed in the overall development and throughout the product life cycle.” says Mikael Wahlén, Project Manager Hardware Research at Ericsson.