Researchers from the University of South Australia and Zhengzhou University have developed a new textile designed to keep people cooler and more comfortable as global temperatures continue to rise. The lightweight, breathable fabric reflects 96 per cent of incoming sunlight and releases heat and moisture more effectively than traditional materials, offering a potential boost to personal comfort and safety during extreme heat.

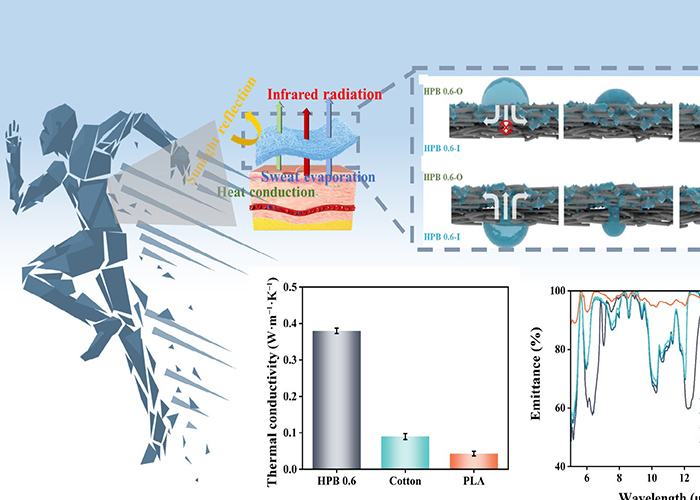

In outdoor field tests, the fabric reduced skin temperature by about 2°C under direct sunlight and nearly 4°C at night compared with bare skin. Unlike cotton, which can retain heat and trap sweat, the composite material actively dissipates warmth while wicking moisture away from the body.

The textile is made from a combination of biodegradable polylactic acid and boron nitride nanosheets. Using an electrospinning process, researchers embedded the nanosheets into a nanofibre matrix to create a white, breathable fabric with five times the airflow of cotton. The material’s structure enhances solar reflectance and radiative cooling, helping the wearer stay cooler without any external power source.

UniSA’s Professor Jun Ma said the development addresses an urgent need as more regions experience extreme heat, particularly affecting outdoor workers, athletes and communities without reliable cooling. He noted that the aim was to create a passive cooling solution by using natural physical processes rather than energy-consuming systems.

Associate Professor Yamin Pan of Zhengzhou University said UniSA’s expertise helped refine the material’s thermal performance, highlighting the value of international collaboration in developing sustainable materials.

Because the fabric is primarily derived from biodegradable PLA, it aligns with growing interest in environmentally responsible material choices. The researchers believe it could be adapted for sportswear, work uniforms, emergency services clothing and other applications where cooling and breathability are critical.

The team is now exploring opportunities for commercial production, noting that the electrospinning process can be scaled for industrial manufacturing. They say the technology has strong potential to influence the next generation of cooling textiles as cities adapt to hotter, more challenging climates.

The research is published in Nano Research.