Marine fouling continues to impose major economic costs on the global shipping industry, damaging vessels and structures while driving up fuel consumption and biosecurity risks. Now, researchers at Flinders University have demonstrated a new antifouling coating that prevents macrofouling and reduces microfouling attachment — without harming the marine environment.

The research team has developed a novel electrochemically active coating that avoids the environmental drawbacks of existing antifouling paints, which typically rely on slow-release biocides and heavy metals.

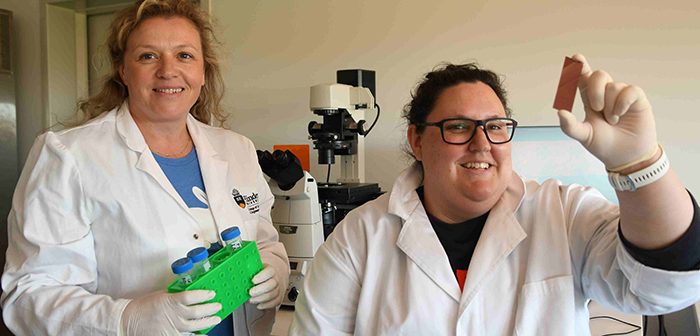

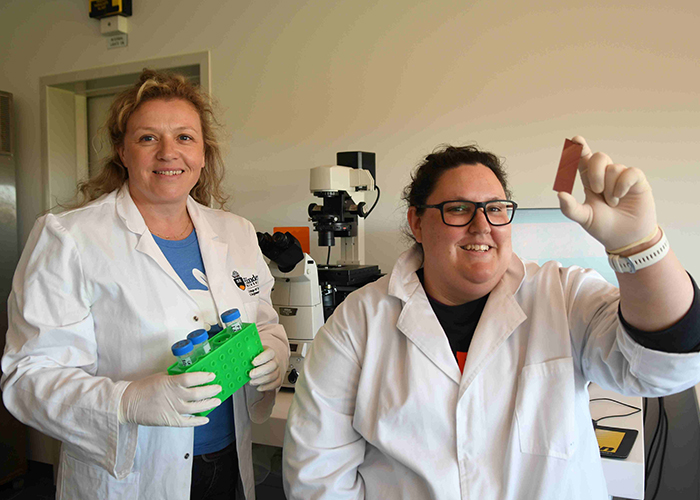

“The development of an environmentally friendly antifouling treatment could revolutionise the shipping industry and eliminate any biosecurity risks,” says lead researcher Dr Tamar Jamieson (pictured – R) from the ARC Training Centre for Biofilm Research and Innovation.

Items painted with the new coating were submerged in the Port Adelaide River harbour basin for 55 days. Scanning electron microscopy, flow cytometry and 16S amplicon sequencing were used to assess performance. The results showed no macrofouling on any treated surfaces, along with a marked reduction in attached microorganisms.

“Current antifouling coatings cause concerns of heavy metal pollution in harbours, marinas and coastal waters. The new environmentally friendly treatment eliminates those concerns,” says Professor Mats Andersson, senior author and a researcher with the Flinders Institute for Nanoscale Science and Technology.

While microfouling could not be fully prevented, electrochemical activity significantly reduced cell attachment. “This novel electrochemically active coating could effectively reduce macrofouling – and, with further development, also microfouling,” Professor Andersson says. “It marks a significant positive development in controlling biofouling.”

Professor Sophie Leterme (pictured – L), director of the ARC Biofilm Research and Innovation Training Centre at Flinders, says reducing biofouling directly supports global sustainability goals. Heavy biofilm accumulation is associated with up to 40 per cent higher fuel consumption in naval and commercial ships and contributes to the spread of exotic marine pests via international shipping routes.

Improving corrosion and biofouling control systems could deliver significant economic and environmental benefits across maritime industries.

The research, titled ‘Prokaryote Fouling Communities on Novel Electrochemically Active Coatings after Submersion in Port Adelaide River Harbor Basin’, has been published in ACS ES&T Water.