Researchers at Flinders University have demonstrated a new way to create and recycle advanced polymer materials using ultraviolet light, offering a potential pathway toward more sustainable plastics suited to smart city and circular economy applications.

Published in the Journal of the American Chemical Society, the research shows for the first time that sulfur-rich polymers can be synthesised and recycled using low-cost, widely available energy sources such as UV light and LEDs. The approach significantly reduces reliance on high temperatures and toxic chemicals traditionally associated with polymer manufacturing, while improving recyclability.

Sulfur-rich polymers are attracting increasing attention as alternatives to conventional plastics, particularly because they can be produced using waste sulfur from industrial processes. Over the past decade, the Flinders research team has demonstrated that these materials can be adapted for a range of high-value uses, including environmental remediation, infrared optics and antimicrobial applications. The latest work expands that potential by making the materials easier to manufacture and reuse.

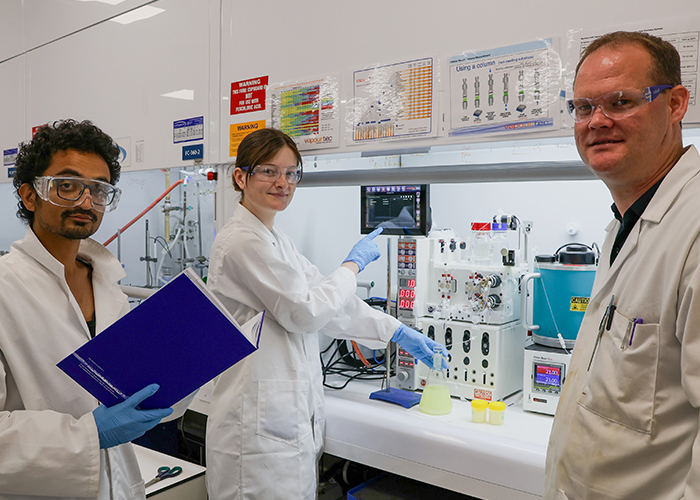

The study was led by Dr Thomas Nicholls, a green chemistry researcher at Flinders University, in collaboration with scientists from the University of Tasmania and Deakin University. The team showed that polymerisation could be initiated simply by exposing the molecular building blocks to UV light, while carefully controlled pulses of LED light were used to prevent degradation during the process.

By precisely regulating the concentration of reactive radicals during polymer formation, the researchers were able to produce high molecular weight polymers suitable for practical applications. These include recyclable adhesives, photoresists used in lithography, and anti-corrosion coatings — materials that are directly relevant to urban infrastructure, manufacturing and electronics.

The same light-based approach can also be reversed. By applying UV light or moderate heat, the polymers can be depolymerised back into their original components and reused. This ability to “make and unmake” materials using simple energy inputs addresses a key limitation of many modern plastics, which are difficult or uneconomic to recycle once deployed.

Global plastic production now runs into hundreds of millions of tonnes annually, contributing to long-term environmental pollution and significant carbon emissions from energy-intensive manufacturing. For smart cities grappling with waste management, infrastructure longevity and sustainability targets, materials that are both high-performance and genuinely recyclable are becoming increasingly important.

Co-author Dr Jasmine Pople described the method as enabling access to sulfur polymers under mild, safe and sustainable conditions, while Dr Harshal Patel highlighted the use of pulsed light as a way to better understand and control recyclability at a molecular level.

Beyond urban materials, the research has implications for resource recovery. Dr Nicholls has recently received a $500,000 Australia’s Economic Accelerator Ignite grant to scale up a related sulfur-polymer technology for gold extraction from ore and electronic waste, reinforcing the role advanced polymers may play in future recycling and circular economy systems.

As cities invest in smarter, more sustainable infrastructure, innovations in materials science such as this highlight how low-energy chemistry and waste-derived materials could underpin the next generation of urban technologies.