A South Korean public corporation overseeing domestic LNG operations has deployed optical gas imaging and artificial intelligence to strengthen methane leak monitoring at the Boryeong LNG Terminal’s pressure regulation facilities.

In 2025, the operator introduced the FLIR GF77a optical gas imaging (OGI) camera as part of an upgrade to monitoring systems at the site. The deployment combines real-time thermal imaging with an AI-based plume detection engine designed to identify methane leaks, particularly in outdoor, unmanned environments where fixed gas sensors may have limitations.

LNG pressure regulation facilities are critical infrastructure and are typically equipped with fixed gas detection sensors. However, according to the facility manager, outdoor installation and remote operation created challenges for early leak detection, prompting the search for complementary technologies.

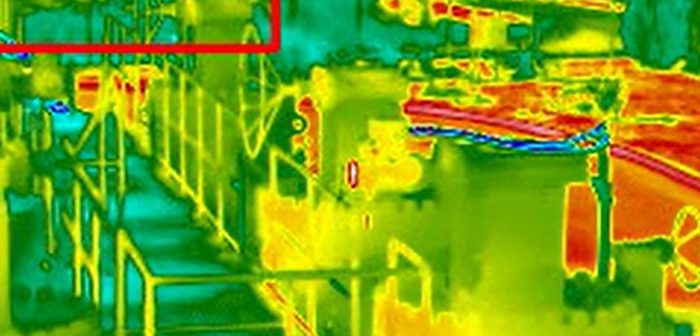

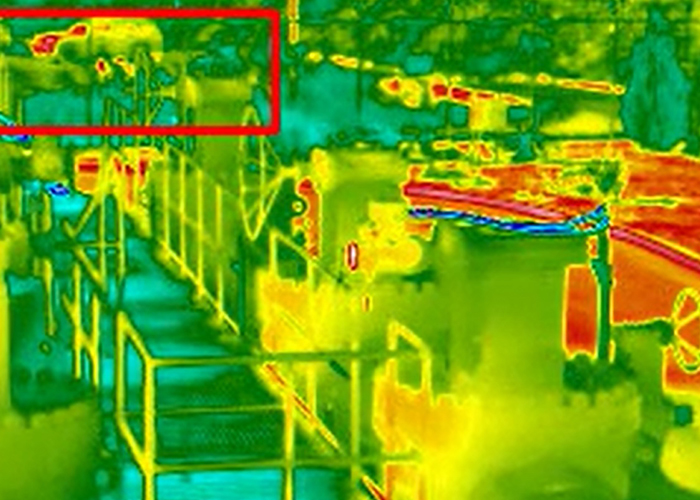

Before full deployment, the operator conducted on-site validation by releasing a controlled sample of methane to test detection performance. The GF77a, which is tuned for methane visualisation, enabled operators to observe gas release patterns in real time. Following successful trials, the camera system was installed alongside the site’s existing CCTV infrastructure.

The system is pole-mounted to provide a field of view across the outdoor pressure regulation area and operates via a network configuration similar to standard surveillance cameras. Real-time OGI video feeds into an AI analysis engine that detects plume patterns automatically. When a potential leak is identified, the system triggers alarms and logs the event for operator response.

The operator reported that the approach provides wider coverage without requiring multiple dedicated gas cameras and leverages existing infrastructure, reducing installation complexity. Unlike sensor-only systems that measure gas concentration at specific points, the OGI-based solution enables visual monitoring across broader areas, potentially improving early awareness of abnormal conditions.

While the system is in early stages of operation, the facility manager noted that sensitivity tuning and environmental adjustments remain areas for refinement. Future plans include improving AI models to account for site-specific conditions, expanding monitoring coverage across the facility, and extending automation to additional gas-related equipment.

The deployment reflects a broader trend toward combining thermal imaging and AI analytics to complement conventional sensor networks in critical energy infrastructure, particularly in environments where continuous on-site human monitoring is limited.